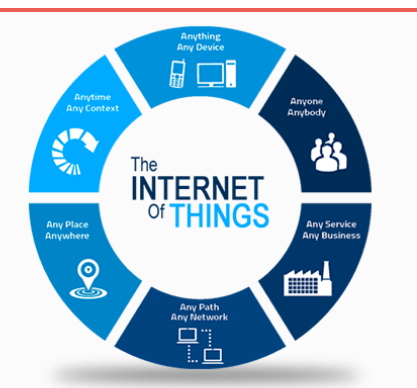

The Internet of Things (IoT) is the network of physical objects that are embedded with software, sensors, or technology that connect them to the internet and other devices. With over 10 billion connected IoT devices today, everything from normal household objects to sophisticated industrial equipment are connected. IoT has unlocked a hyperconnected world where the line between physical and digital is blurred.

The Industrial Internet of Things (IIoT) refers to the use of IoT technology within the industrial, plant floor setting. IIoT uses a combination of sensors, bid data, artificial intelligence, analytics, and wireless networks to optimize and automate overall production process.

IIoT empowers manufacturers to automate & optimize their overall operating efficiency. Relying on robotics & automated equipment improves overall production efficiency & accuracy, boosts productivity, helps streamline processes.

Using equipment sensors, machine and equipment data can be monitored on a consistent basis. This data provides visibility into equipment OEE and allows manufacturers to make data-driven decisions regarding all manufacturing functions.

According to a Cyber Security Trend report, human error accounts for 37% of all data breaches. Utilizing IIoT allows manufacturers to digitize every part of their business.

IIoT has provided manufacturers with another way of protection. Using intelligence, connected devices, and wearable monitors, managers can now monitor the health, safety, and protection of their workers.

Unplanned downtime is the nightmare of manufacturers worldwide. The average cost host of downtime across all manufacturing types equates to $260,000/hour (Aberdeen Research Group).

From equipment breakdowns and unforeseen bottlenecks to supply chain disruptions and complex customer orders, inefficient manufacturing processes result in loss of production time and profit.

Relying on data-driven insights to direct operations & production can help steer manufacturers in a profitable direction. Combining other IIoT benefits, like predictive maintenance, reduced errors, & improved efficiency & quality, all reduce operating costs & boost profit.

IIoT allows quality control to be automated, reducing the risk of human error and improving overall quality. Machine-equipped sensors monitor for material quality, defects, and overall equipment performance.

Inventory management can be a constant challenge within manufacturing. Over or understocking the correct parts to keep production running smoothly is a time-intensive process.

One of the clearest and most compelling benefits of IIoT is the ability to remotely monitor equipment & production 24/7 from virtually anywhere. A 360-degree view of the plant floor paired with specific insights into equipment & production.

© 2022, GR Industrial Automation Systems. All Rights Reserved.